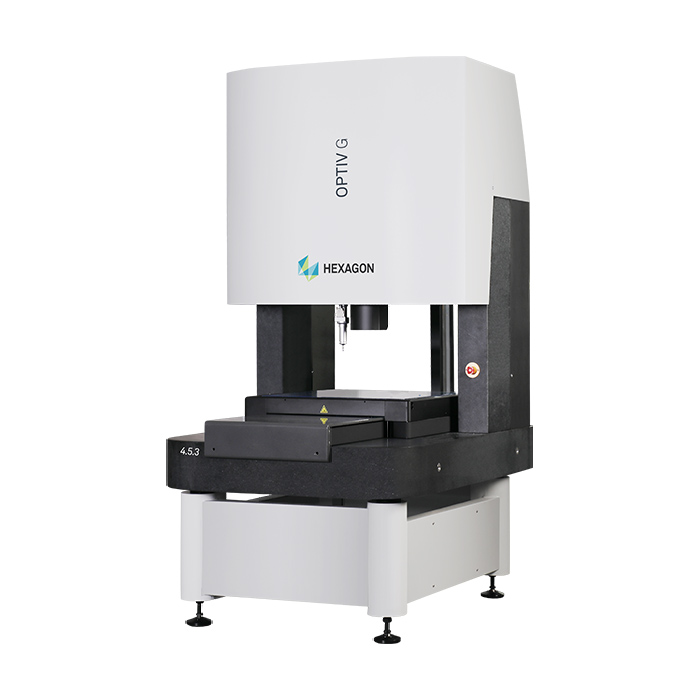

The patented dual Z-axis composite measurement technology achieves measurement accuracy within the submicron range, creating a new high in image precision measurement technology. The combination of optical measurement and contact measurement in one system greatly improves the measurement efficiency and application flexibility of the composite image measuring instrument. PERFORMANCE/M is also equipped with dual Z-axis technology, further shortening the testing cycle, reducing testing costs, and improving the reliability of measurement results.

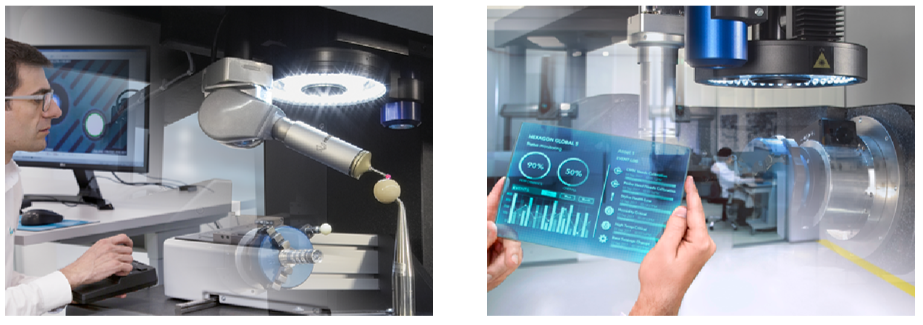

Integrating multiple sensors to complete complex measurement tasks

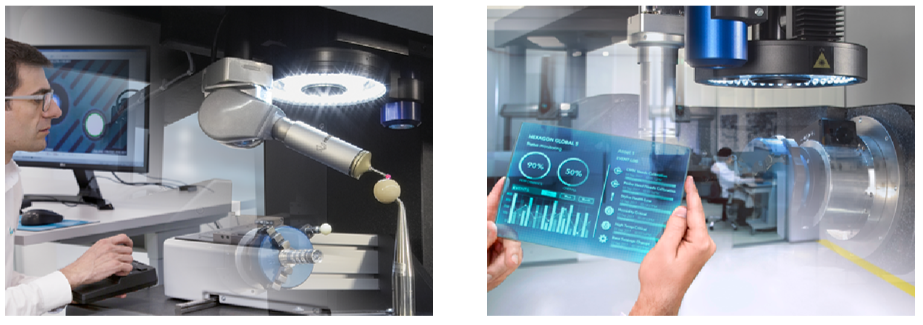

The Optiv PERFORMANCE/M series image measuring instruments are widely used in industries such as 3C electronics, semiconductors, precision machinery, medical, aerospace, and metrology institutes.

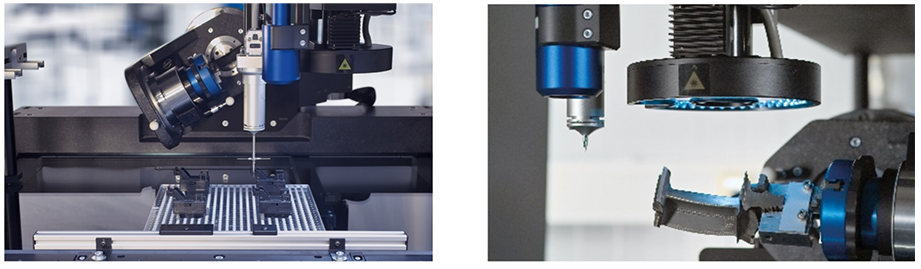

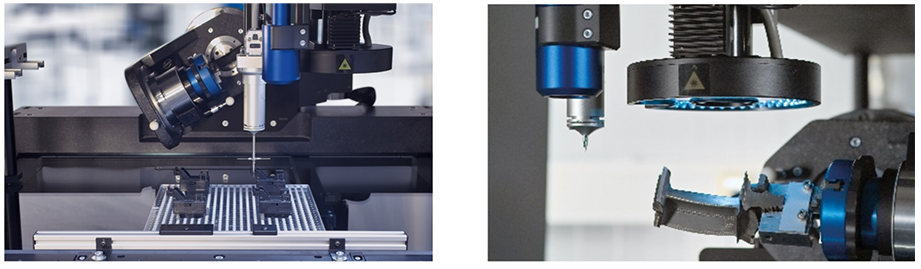

1) CCD image:

Perform non-contact measurements on small, thin, soft, and precise measured features to avoid deformation.

2) CWS white light:

Perform sub micron precision measurements on soft, reflective, or low contrast surfaces.

3) Contact scanning:

Perform single point triggering and continuous scanning measurements on unrecognized 3D features that cannot be completed in the image.

Product advantages:

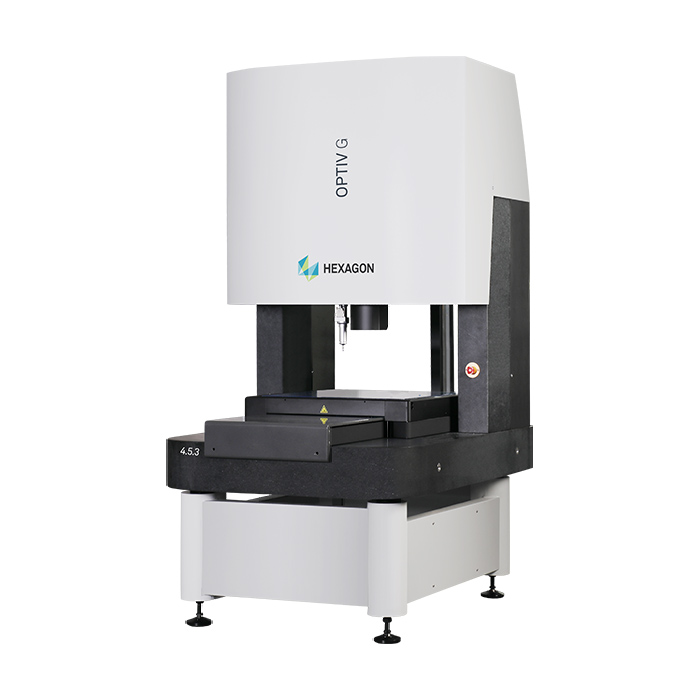

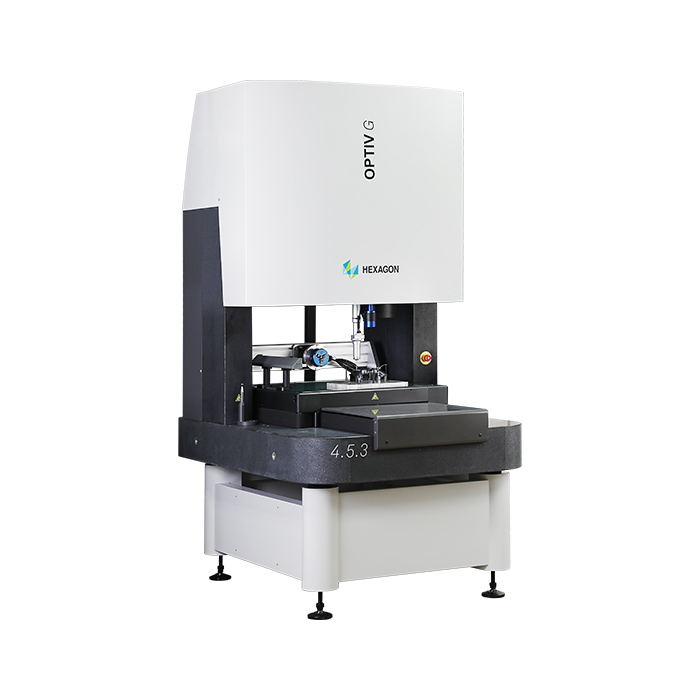

The rich high-end composite image measuring instrument Optiv PERFORMANCE/M series has high reliability, integrating imaging, white light, contact, and 3D scanning technology into a system, quickly completing various feature measurements with one clamping and one setting.

· Flexible optical lens selection; Electric zoom lens, 2-Step Zoom;

· Diversified sensors, trigger contact probe, HP-S-X1 continuous scanning probe, probe replacement rack, confocal white light;

· Adopting a fixed bridge and mobile workbench structure;

· All three axes are centrally driven to reduce Abbe error;

· Coaxial light, transmitted light, multi segment surface annular light;

· Equipped with industrial grade black and white or color CCD cameras;

· Dual Z axis design (Dual Z model);

· HA or UHA high-precision models are optional;

· Equipped with PC DMIS VISION software�;

· Precision ball screw and linear guide rail�����;

· Precision single or double turntable;

· Equipped with PC - DMIS VISION software����。

More efficient and accurate detection configuration

1) Dual Z-axis, non-interference between contact and optical measurements, saving detection time and reducing collision risk.

2) Dual turntable, fully integrated CNC turntable automatically adjusts workpiece position, expands detection range, and improves measurement flexibility.

3) Dual lens, OPTIV dual CCD technology, balancing fast edge finding and high-precision detection, reducing accuracy loss.

Powerful PC-DMIS VISION measurement software

PC-DMIS VISION is a composite measurement software developed by HEXAGON for image measurement machine users. It adheres to the core technology of the measurement software PC-DMIS, with an intuitive operating interface and intelligent feature automatic recognition function. Offline programming operation and simulation optimization of detection paths make this software easy to learn, efficient and practical.

· Full Chinese interface, with direct mouse click operation, can automatically capture and measure circles, points, lines, and surfaces for general geometric measurements;

· Implement input and output of CAD documents in formats such as IGES and DXF;

· Can directly calibrate the size of the measured elements on the image, which is clear and intuitive;

· The measuring workpiece can be placed arbitrarily, and the software has powerful coordinate translation, rotation, or reset functions;

· Easy programming for automatic measurement;

· Powerful boundary judgment methods: four boundary selection methods: dominant edge, closest nominal value, matching edge, and dominant edge;

· Intuitive and rich report output.