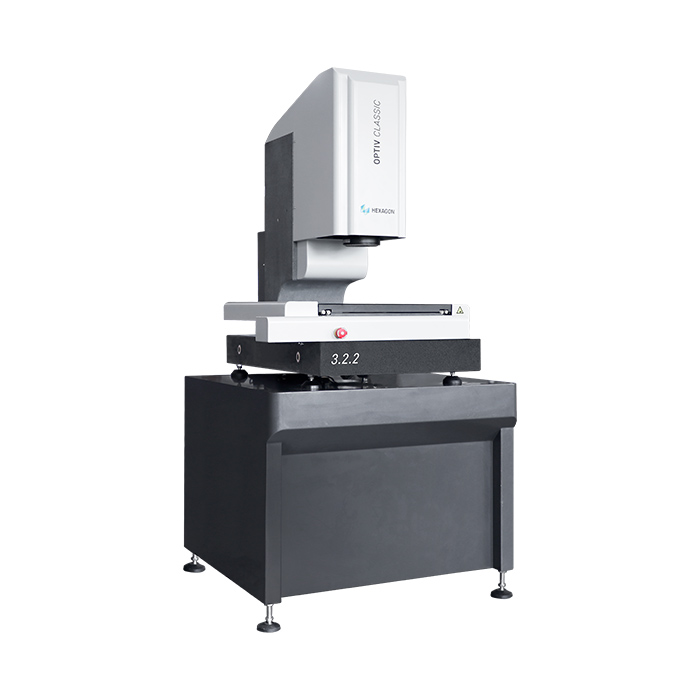

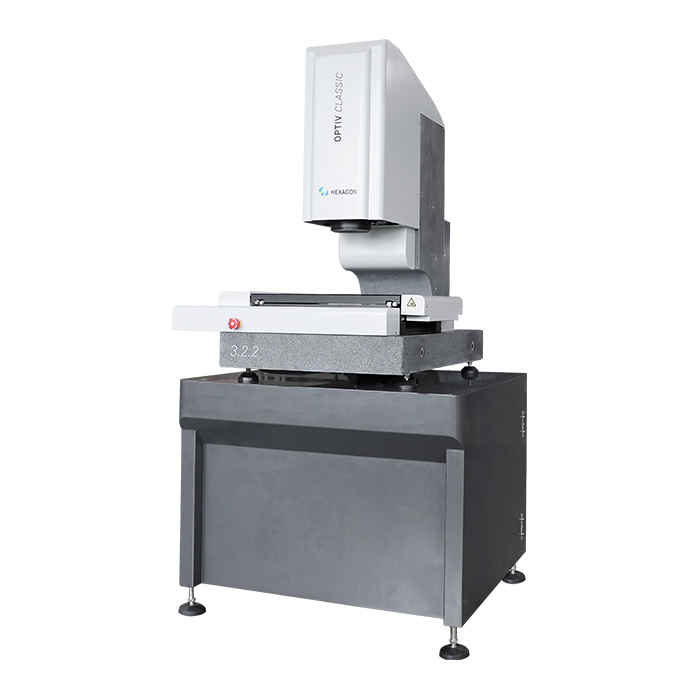

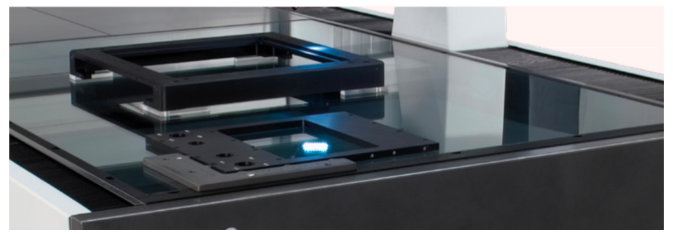

OPTIV Classic is equipped with an industrial grade color CCD camera and an optional trigger probe. High efficiency, high stability, high cost-effectiveness, long travel, meeting various measurement needs.

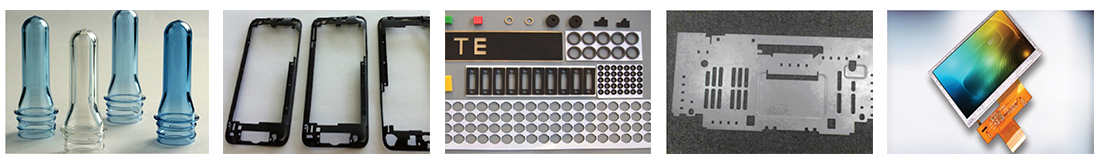

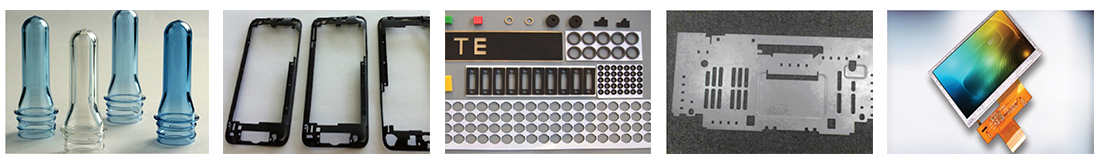

Wide application range and strong practicality

OPTIV CLASSIC is equipped with an industrial grade color CCD camera, which quickly locates the position of the measured features through a laser indicator. With an optional trigger probe and advanced algorithms, it can quickly measure various small, thin, and soft components. It is widely used for measuring workpieces such as injection molding, die-cutting, stamping, PCB, LED, etc.

Measurement plan

1) Plastic products

All dimensions of the inside and outside of the bottle cap, as well as the cross-section, mainly measuring dimensions such as diameter, opening angle, depth, thickness, and width; Customized specialized fixtures.

2) Outer frame

The size of the part is small, and there are many dimensions that need to be measured, such as small R measurement, flatness measurement, fit edge measurement, and contour measurement of the fit position

3) Die-cut parts

Various lengths, widths, diameters, outer contours, positional accuracy, etc. The software has fast measurement functions such as matrices.

4) Connector

Installation hole position, spacing, small R angle slot width, etc.

5) LCD module

The overall dimensions, holes, and positions of 2D glass and panels, as well as the line width, line spacing, and bonding position of the wiring.

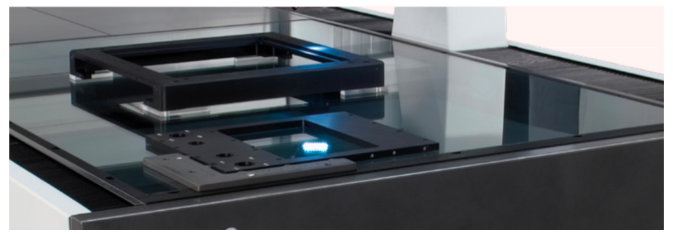

Patented protection for precision over long distances

OPTIV CLASSIC has multiple unique technologies to ensure the dynamic performance and measurement accuracy of the machine over long strokes.

Product advantages

? High speed, high measurement efficiency;

? Adopting high-precision granite base and crossbeam, the overall structure is stable and less affected by temperature changes, ensuring the long-term stability of the machine;

? High resolution color digital camera with high-definition image effects and high-quality images;

? Equipped with fully automatic high-precision zoom lens;

? Coaxial light, transmitted light, multi segment surface annular light;

? Can provide contact triggered probe, confocal white light sensor, laser sensor, and line laser sensor;

? Equipped with METUS or PC DMIS VISION measurement software.