As an entry-level model in the OPTIV series, the OPTIV LITE has high reliability and good dynamic performance, and can be equipped with laser sensors or white light confocal sensors on top of optical sensors. It is a professional 2.5D image measuring instrument with high cost-effectiveness.

Product Features

· Support CNC program repeated editing and data refresh

· Adding the LOOP loop function can achieve array functionality.

· There are various ways to establish a coordinate system, and the translation and rotation of the coordinate system are very convenient. Simultaneously supporting the establishment of multiple coordinate systems in a CNC program, it is very convenient to perform callbacks.

· Splice multiple sub images together to synthesize a panoramic view of the workpiece. Panoramic maps can be used for navigation maps during CNC creation.

· METUS has powerful image processing algorithms, especially in terms of clutter filtering and edge grabbing methods, drawing on the advantages of PC-DMIS. By combining edge grabbing methods, edge polarity, strength, and outer filtering, it can better measure various complex workpieces.

· Visually display the distribution of the original points of each grabbing element for easy analysis.

· One operator can operate multiple machines, saving labor and improving efficiency.

· Support for 3D scanning module

Stable performance, complete functionality, meeting different testing needs of customers

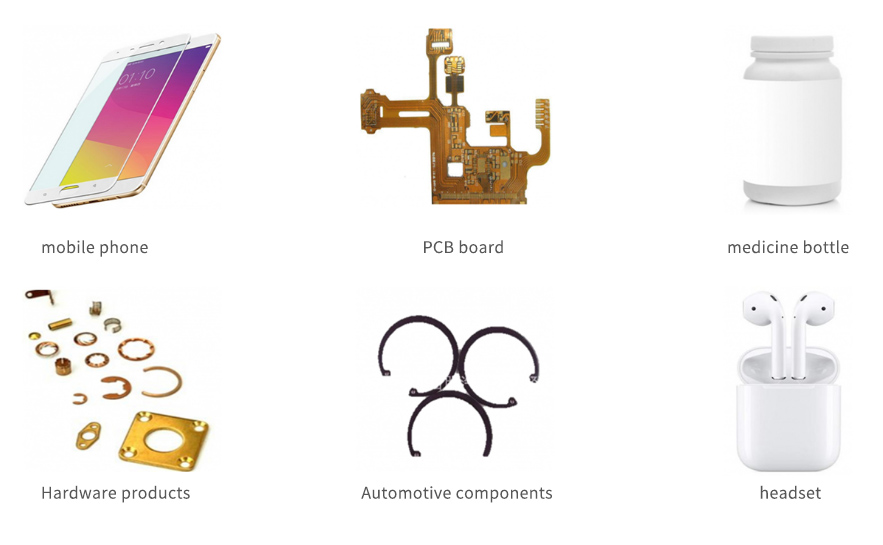

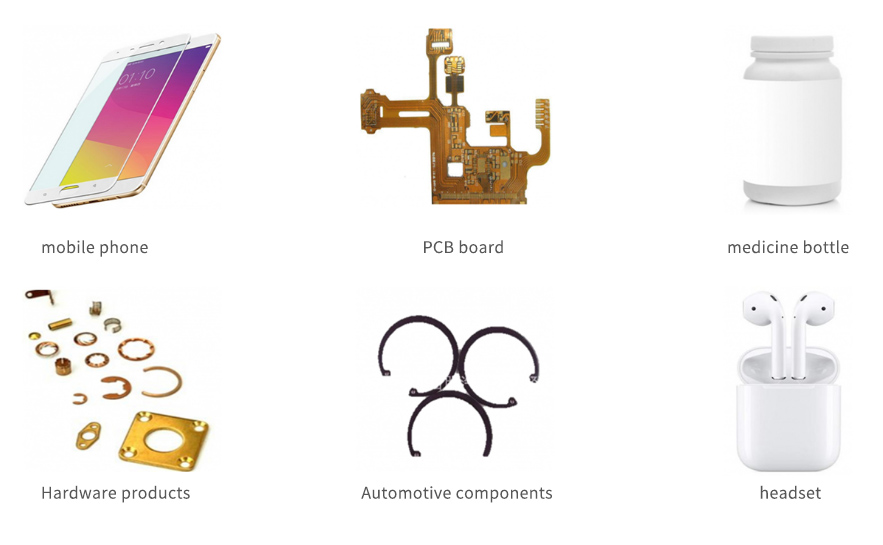

OPTIV is a high-end series in the Hikvision imaging system. The entry-level OPTIV LITE has the stable accuracy and good dynamic performance shared by the OPTIV family, and is widely used in industries such as mobile phones, PCB boards, hardware products, medical devices, automotive parts, headphones, and manufacturing products.

Product advantages

· The base, columns, and working platform of the host are all made of high-precision granite material, ensuring the long-term stability of the machine;

· Three axis configuration full servo closed-loop control system, silent P-level linear guide rail transmission, suitable for high-speed motion and high-precision positioning;

· Configure high pixel and high-resolution color CCD to ensure clearer imaging effect;

· Equipped with a fully automatic zoom lens;

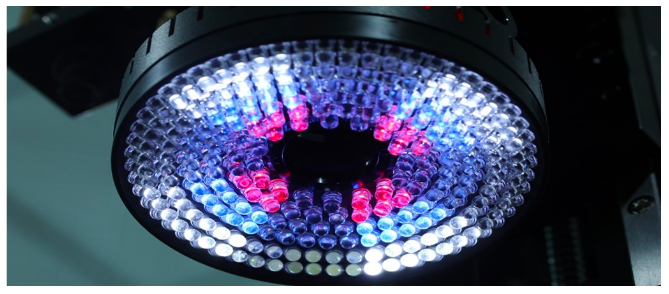

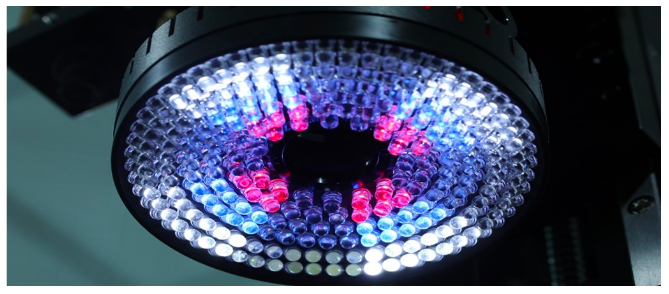

· Equipped with six rings and eight zones of circular light, different light effects can be programmed to ensure accurate measurement results;

· Upgradeable to fully automatic programmable lifting and lowering of ambient light to meet different product lighting needs;

· Standard navigation system, convenient for users to write and run programs;

· Select wiring laser sensors and confocal white light sensors.

Powerful METUS measurement software

METUS is a full vision measurement software designed and developed by a Hexconn software design team with years of industry experience based on PC-DMIS.

METUS adheres to the core technology of the measurement software PC-DMIS and is specifically developed for imaging products.

In the development process of METUS, in addition to implementing the concept of meticulous measurement standards, the principle of easy learning and easy use has also been implemented.