The RigelScan intelligent handheld laser 3D scanner is a newly launched measurement system that can finely scan small features and obtain accuracy certification from the National Academy of Metrology. RigelScan handheld scanning triangulation positioning technology is not constrained by factors such as object material and color, and can be equipped with wireless modules to achieve flexible scanning of large-sized workpieces, bringing users a more efficient and free 3D scanning experience.

Product characteristics:

Product advantages:

1�、Metrological level accuracy

The accuracy can reach up to 0.01mm, with fine mode scanning of small features to truly restore the surface details of the workpiece. The RigelScan series has been certified for metrological accuracy by the National Academy of Metrology.

2、Efficient measurement

Scan format up to 600 × 550mm, with a measurement rate of up to 1.35 million measurements per second, the overall scanning rate is 2.2 times higher than mainstream 7-line products in the market.

3���、Strong adaptability

Pure blue light technology has strong anti-interference ability, faster scanning speed, more accurate data collection, and can easily obtain dark or bright surface data. Standard and fine dual blue light modes can be freely switched to adapt to different workpiece features.

4、Wireless operation

Optional wireless module for flexible adaptation to large-sized workpieces and easy handling of complex working conditions

5�����、Quick switching

The scanner has a control mode button that allows for switching between view operation mode and shutter adjustment mode. Adjustments to scanning software related modes can be made without the need for computer keyboard/mouse operation. Including view zoom function, shutter adjustment function, etc����;

6�、 Automatic assembly

Equipped with automatic assembly function, scanning the overall marker points first, and then scanning each part separately. The scanning results of each part can automatically complete the splicing���;

7����、Scanning resolution can be adjusted at any time

Before, during, or after scanning, the overall resolution can be changed at any time to generate a new resolution model. And it supports overall resolution changes to the saved data engineering, generating models with different resolutions. Users only need to scan once to adjust different resolutions using the scanning engineering, and select the optimal resolution effect based on the effect of different resolutions���;

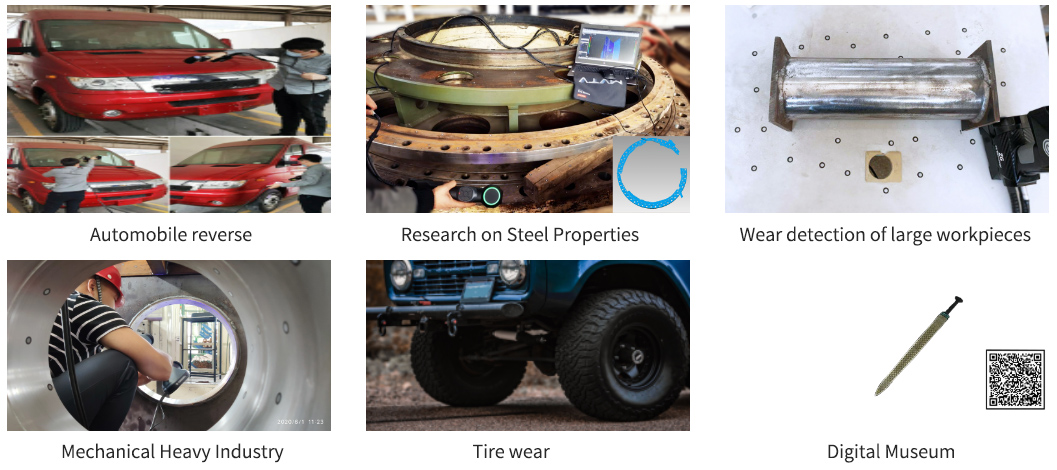

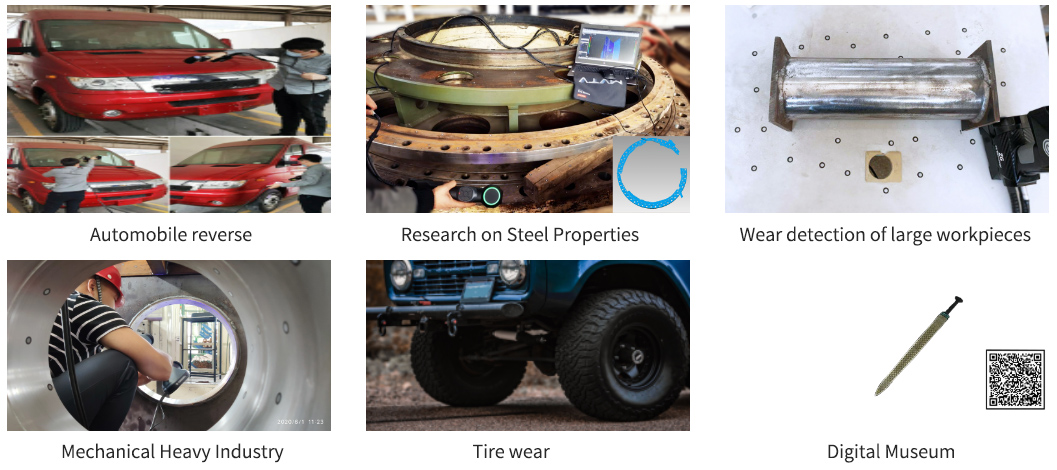

Application direction:

1. Automotive industry: vehicle scanning, competitor analysis, automotive design, component measurement, aesthetic design, etc;

2. Tire industry: wear detection, compression deformation analysis, cross-sectional line analysis, mold quality inspection, reverse design, etc�;

3. Sheet metal industry: reverse design, external dimension testing, rebound detection analysis, etc����;

4. Forged castings: inspection of casting molds, reverse design, assessment of clamping gaps, deformation detection, structural characteristic analysis, etc;

5. Construction machinery: quality inspection and control, reverse design, mechanical fixture design, mold adjustment, etc;

6. Cultural and museum applications: cultural relic scanning, ancient building protection, virtual restoration, mural detection, etc;